Validity: 45 days

Model Description QTY | ||||

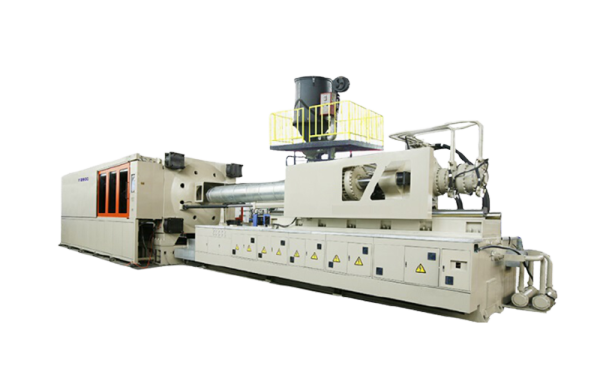

TF3015D Fiber Laser Cutting Machine | Effective cutting area | 3000x1500mm | ||

Laser max cutting thickness | 6mm(Mild Steel) | 1 set | ||

FOB Shanghai$26,000 | ||||

Production time | Within 45 days after advance payment | |||

Payment term | 30% T/T in advance, balance before delivery | |||

Packing | Plywood case and tray | |||

Container requirement | 20'GP container | |||

Warranty: 12months from the date of bill of lading issued.(Seller will supply free spare parts by mail)

Installation, training and commissioning service terms:

Time cost: 1 engineers 10-15 days

Engineer's visa fee, round-trip flight tickets from Shanghai to user's spot, food and accommodation cost undertaken by buyer.

Engineer's subsidy 80.00 USD per day, per person.

Buyer takes responsibility to arrange a Chinese speaking translator to be assistance during installation and training.

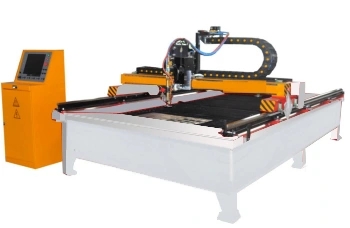

*Product images and cutting parameter inside of this file are for illustrative purposes only and may differ from the actual product!

Technical Specification

1.Machine Parameter

2. Main Components

Effective Cutting Area | 3000×1500 mm |

X Axis Cutting Length | 3000 mm |

Y Axis Cutting Width | 1500 mm |

Max Cutting Thickness | 6mm(Mild Steel) |

Position Speed | 50 m/min |

X Y Axis Position Accuracy | 0.05 mm |

X Y Axis Repeat Position Accuracy | 0.025 mm |

Fiber Laser Generator | Feibo 500W |

Machine Noisze | <75db |

Working Voltage | 3 Phase 380V±5%/50Hz |

Machine Outer Dimension(L×W×H) | 5.6×2.9×1.9m |

Power Requirement | 13.8kW |

No. | Item | Brand | Note |

1 | Fiber Laser Generator | Feibo | 500W |

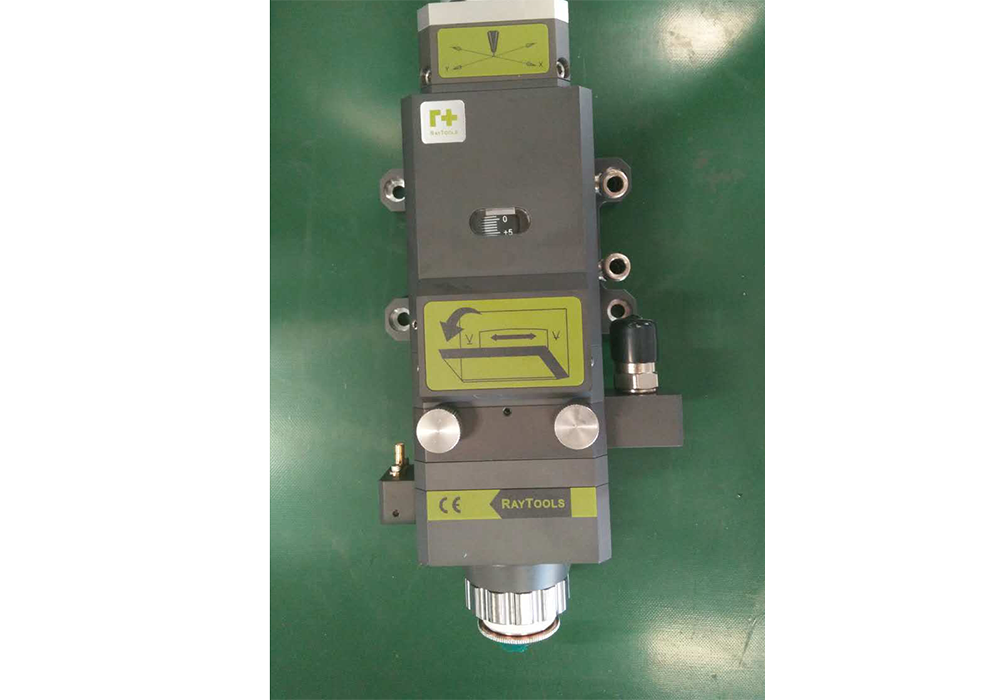

2 | Fiber Laser Cutting Head | Raytools | |

3 | Machine Body | Our factory | |

4 | Beam | Our factory | |

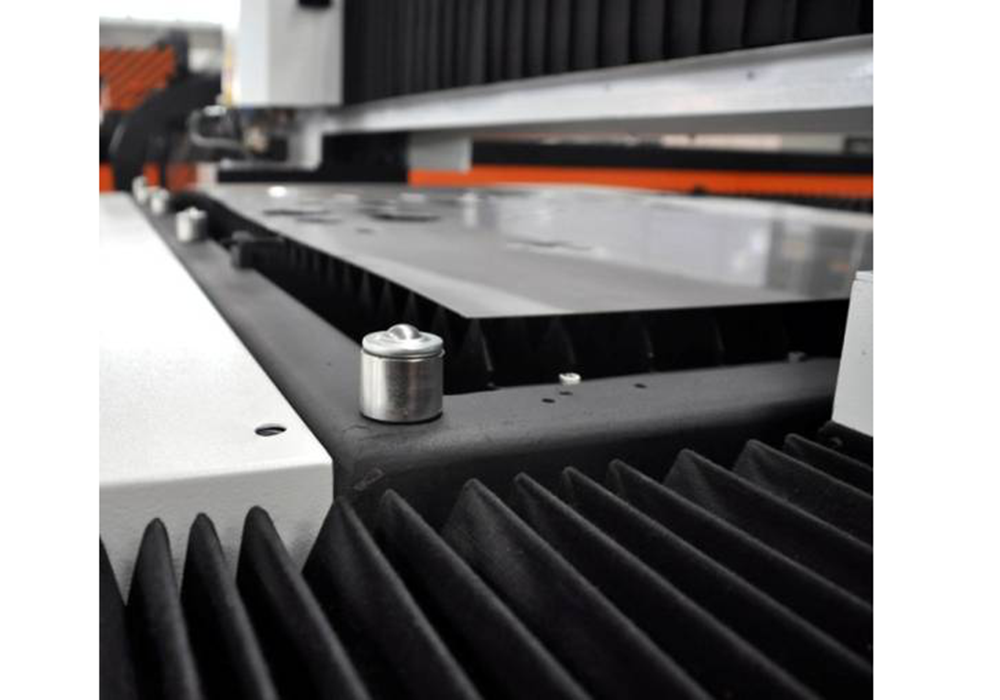

5 | Cutting Table | Our factory | Single Table |

6 | Precision Gear Box | Taiwan Shimpo | |

7 | Linear Guide | Taiwan LMA | |

8 | Gas System | Japan SMC | |

9 | Cooling Unit | Tongfei | |

10 | Electric Components | France Schneider, etc. | |

11 | CNC Controller(Including Software) | CypCut | |

12 | AC Servo Driver & Motor | Japan Fuji | |

13 | CAD/CAM Nesting Software | CypCut | |

14 | Electric Cabinet & Operation Table | Our factory | |

15 | Dust Collection | China Brand | Including Blower |

16 | Scrap Collection | Our facotry |

3. Cutting Thickness And Speed

Cutting parameter based on SS(Stainless Steel SS304); MS(Mild Steel Q235). Below cutting parameters are for reference only!

Material | Thickness | Recommend Cutting Speed | Max Cutting Speed | Power | Cutting Gas | Gas Pressure | Focus | Nozzle Model | Defocusing |

SS | 0.8 | 7000 | 10000 | 500 | N2 | 10 | -3 | 1.5 | 0.7 |

SS | 1 | 6500 | 9000 | 500 | N2 | 10 | -3 | 1.5 | 0.7 |

SS | 1.5 | 4500 | 5000 | 500 | N2 | 12 | -5 | 1.5 | 0.7 |

SS | 2 | 1700 | 2000 | 500 | N2 | 12 | -5 | 2 | 0.7 |

SS | 3 | 560 | 610 | 500 | N2 | 16 | -8 | 2.5 | 0.7 |

MS | 1 | 5500 | 8000 | 500 | O2 | 120 | 8 | 1.2 | 0.7 |

MS | 1.5 | 4200 | 6000 | 500 | O2 | 120 | 8 | 1.2 | 0.7 |

MS | 2 | 2700 | 4000 | 500 | O2 | 40 | 8 | 1.2 | 0.7 |

MS | 3 | 1600 | 1800 | 500 | O2 | 30 | 8 | 1.2 | 0.7 |

MS | 4 | 1200 | 1500 | 500 | O2 | 30 | 8 | 1.2 | 0.7 |

MS | 5 | 750 | 900 | 500 | O2 | 28 | 8 | 1.5 | 0.7 |

MS | 6 | 650 | 900 | 500 | O2 | 28 | 8 | 1.5 | 0.7 |

4. Machine Rough Consumption

A> Total Power Consumption

Machine Part | Power | Power Consumption | Note |

Laser Generator | 1.6 | ≦13.8 | Due to the power price is different in every country, so I can only give power consumption, couldn't give total price cost |

CNC Table | 5.8 | ||

Cooling Unit | 2 | ||

Extractor | 4.4 |

Gas | Consumption | Note | Note |

O2 | 60 | Calculated based on 1mm MS Plate | Due to the gas price is different in every country, so I can only give gas consumption, couldn't give total price cost |

N2 | 15 | Calculated based on 1mm SS Plate |

C> Consumables

Consumables | Life(Hour) | Unit Price | Total Cost | Note |

Protective Mirror | ≧240 | 43 | 0.18 | If working environment is good, then consumables' life will be longer |

Nozzle | ≧600 | 21.4 | 0.04 | |

Ceramic Ring | ≧1500 | 108 | 0.07 | |

Total | 0.29 USD/Hour | |||

Total Consumption

Item | Power Consumption | Gas Consumption | Consumables | Total Cost | Note |

O2 | ≦13.8 kW/Hour | 60 (Minute/Bottle) | 0.29 USD/Hour | Calculated based on 1mm MS Plate | |

N2 | ≦13.8 kW/Hour | 15 (Minute/Bottle) | 0.29 USD/Hour | Calculated based on 1mm SS Plate |

CNC Controller

- CNC Controller

Laser Source

- Feibo 500W Laser Source

Fiber Laser Cutting Head

- Raytools Fiber Laser Cutting Head

Japan Fuji AC Servo Motor

- Japan Fuji AC Servo Motor

Helical Rack And Pinion

Fireproof Cover In All Axis

- Fireproof Cover In All Axis

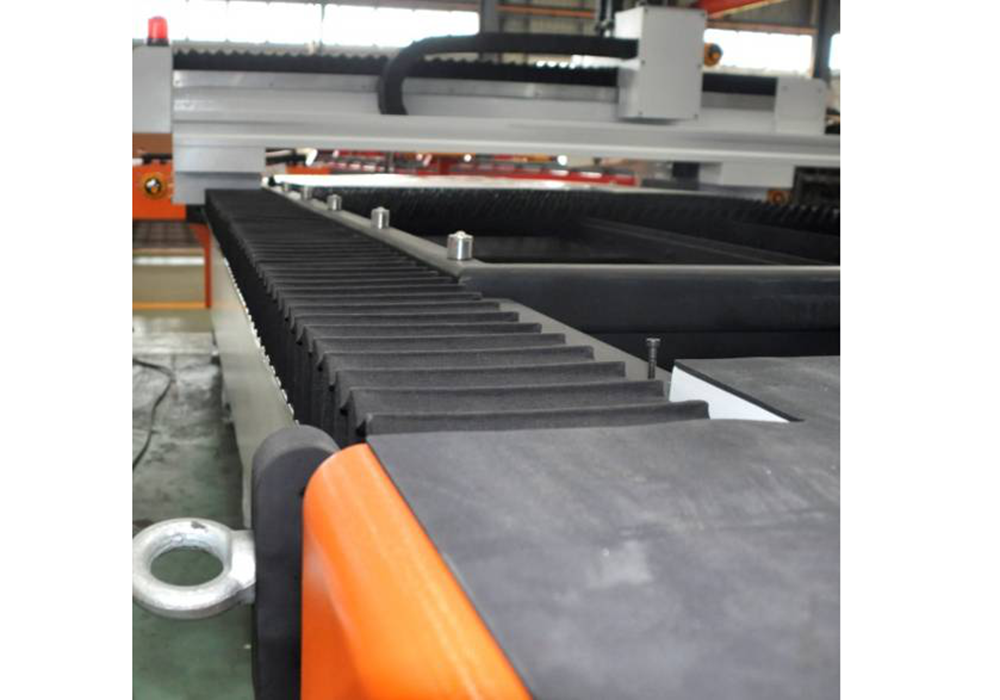

Closed Pedrail In All Axis

- Closed Pedrail In All Axis

Auto Lubrication System

- Auto Lubrication System

Roller For Plate Loading

- Roller For Plate Loading

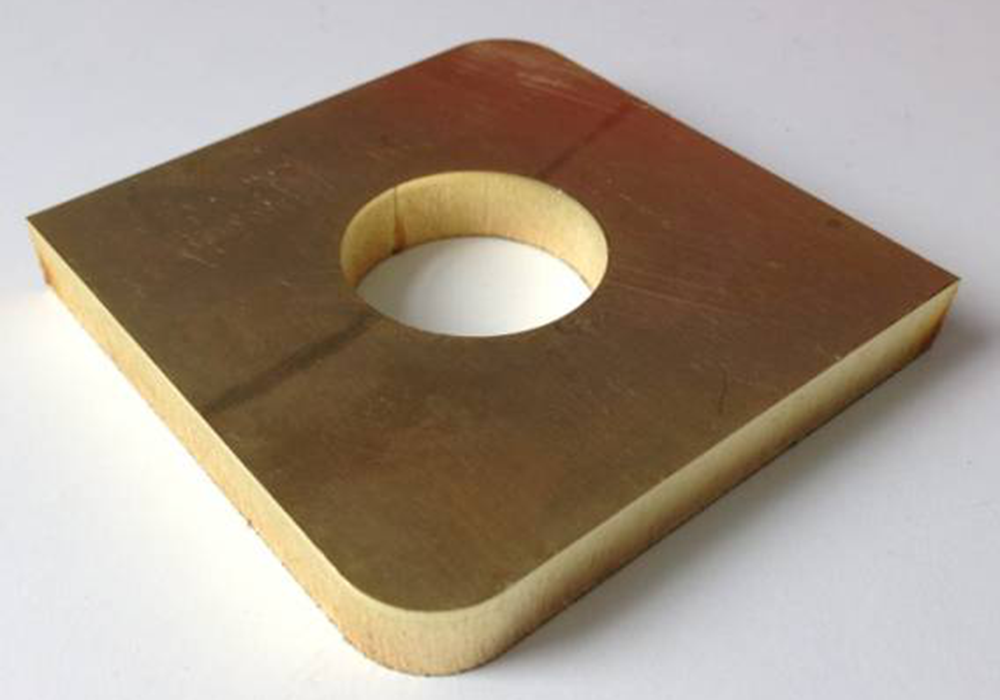

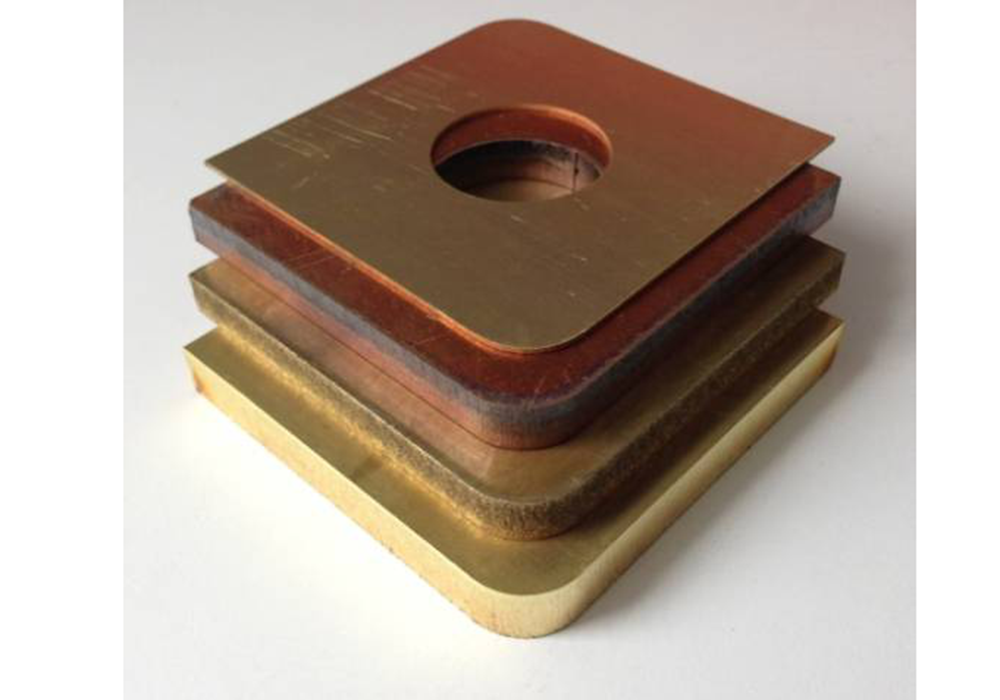

Cutting Sample