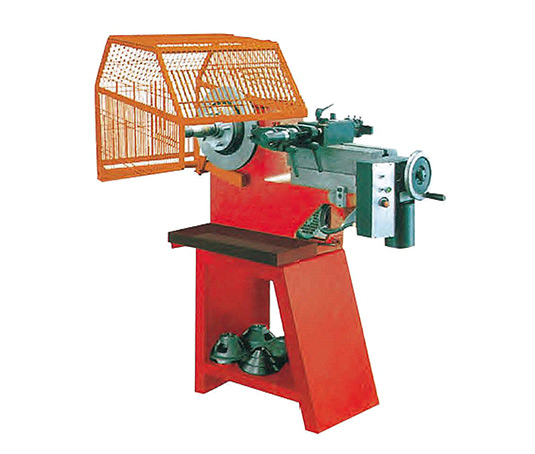

Fin Press Module No: ZCPC-45

Fin Press stroke: 45 tones

Fin Press Speed: 120~200 SPM

Stacker / Collection Unit: 2 Position, 2 position Transverse shuttle

Scraper Collection Method: a Scrap Box

Loading or unloading direction of stock: Left or right when you face the running direction of press. Left

Slit cutting type: 1,2,3,4

Main characters & function:

1. Machine Line includes: Coil Cradle, Oil tank, feeder, Power press, Sucker & Collector, Air system, Electric system, Hydraulic system 2. Vacuum Stucker is controlled by converter 3. Collector has protecting system for fault operation, No material warning, no oil warning 4. PLC control

| |||||||||||||||||||||||||||||||||||||||||||||||||||

Part chose:

- Air valve—ROSS (USA)

- PLC --- Japan

- Converter: YASKAWA Japan

- Pneumatic Solenoid valves: SMC (Japan)

- Electric components: TE (France)

- Pneumatic cylinder: SMC (Japan)

- Induction switch & sensors & inductor: Made in Canada or Japan

Optional:

Industrial Touch-Screen controller

Photo-electric protecting device

Hydraulic overloading system: