Specification | Unit | PR9 060/2550 | |

Max. Bending Force | KN | 600 | |

Max. Bending Length | mm | 2550 | |

Column Distance | mm | 2150 | |

Throat Depth | mm | 350 | |

Ram Stroke | mm | 215 | |

Closed Height | mm | 530 | |

Approaching Speed | mm/s | 200 | |

Working Speed | mm/s | 18 | |

Return Speed | mm/s | 200 | |

Main Motor Power | Kw | 7.5 | |

CNC System | Holland Delem DA66T or DA52S or DA53T or T-3500T CNC system controlling Y1、Y2、X, R, Z1, Z2 axes and mechanical crowning. | ||

Oil Tank Capacity | L | 300 | |

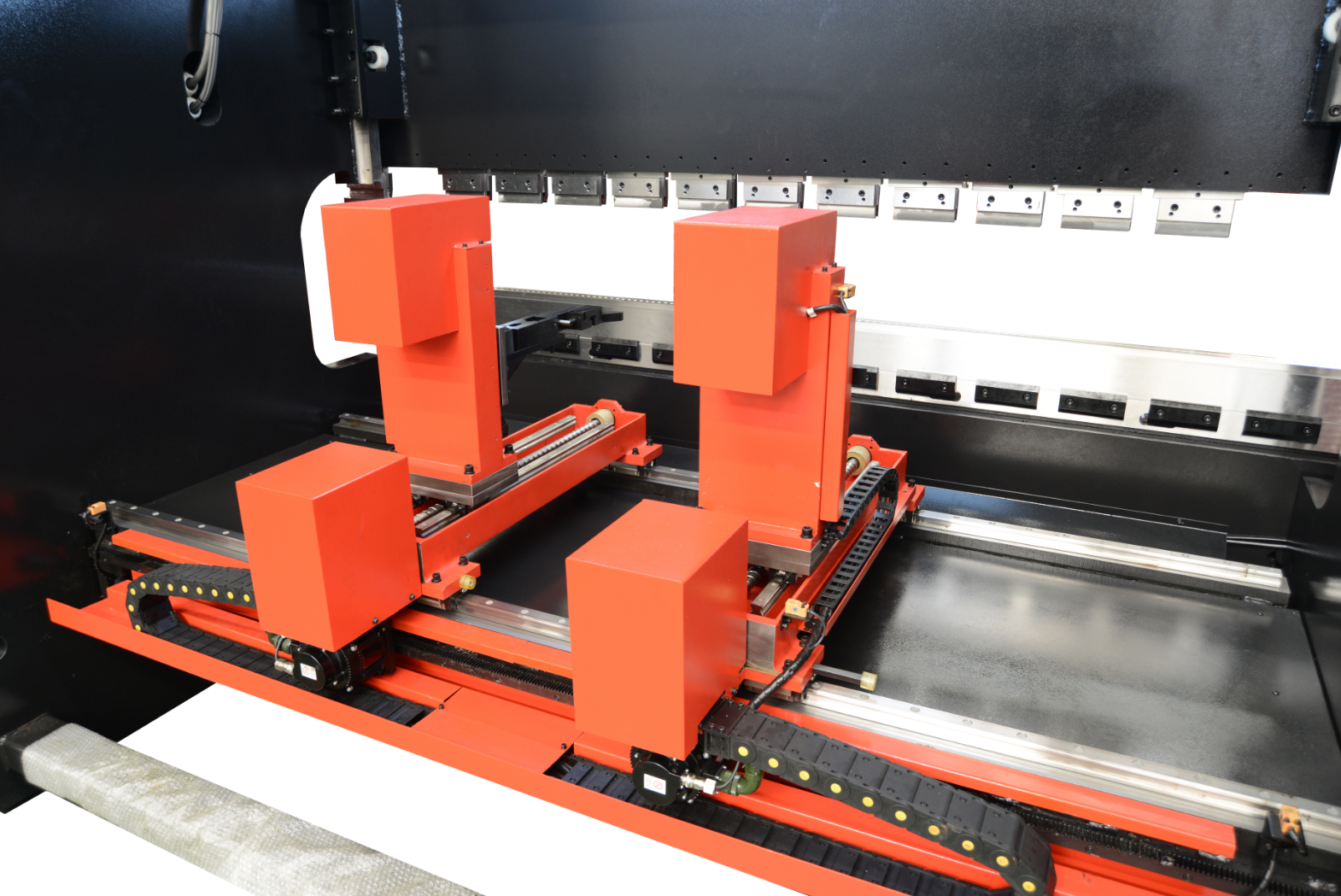

X | Accuracy | mm | ±0.1 |

Stroke | mm | 500 | |

Speed | mm/s | 400 | |

Power | Kw | 0.85 | |

R | Accuracy | mm | ±0.1 |

Stroke | mm | 200 | |

Speed | mm/s | 200 | |

Power | Kw | 0.85 | |

Z1,Z2 | Accuracy | mm | ±0.1 |

Stroke | mm | 1250 | |

Speed | mm/s | 1200 | |

Power | Kw | 0.75 | |

Outline Dimension | Length | mm | 3400 |

Width | mm | 1400 | |

Height | mm | 2510 | |

Specification | Unit | PR9 100/3100 | PR9 100/4100 | |

Max. Bending Force | KN | 1000 | 1000 | |

Max. Bending Length | mm | 3100 | 4100 | |

Column Distance | mm | 2700 | 3700 | |

Throat Depth | mm | 420 | 420 | |

Ram Stroke | mm | 265 | 265 | |

Closed Height | mm | 530 | 530 | |

Approaching Speed | mm/s | 220 | 220 | |

Working Speed | mm/s | 17 | 13 | |

Return Speed | mm/s | 220 | 150 | |

Main Motor Power | Kw | 15 | 11 | |

CNC System | Holland Delem DA66T or DA52S or DA53T or T-3500T CNC system controlling Y1、Y2、X, R, Z1, Z2 axes and mechanical crowning. | |||

Oil Tank Capacity | L | 350 | 500 | |

X | Accuracy | mm | ±0.1 | ±0.1 |

Stroke | mm | 500 | 500 | |

Speed | mm/s | 400 | 400 | |

Power | Kw | 0.85 | 0.85 | |

R | Accuracy | mm | ±0.1 | ±0.1 |

Stroke | mm | 200 | 200 | |

Speed | mm/s | 200 | 200 | |

Power | Kw | 0.85 | 0.85 | |

Z1,Z2 | Accuracy | mm | ±0.1 | ±0.1 |

Stroke | mm | 1850 | 2800 | |

Speed | mm/s | 1200 | 1200 | |

Power | Kw | 0.75 | 0.75 | |

Outline Dimension | Length | mm | 3450 | 4450 |

Width | mm | 1600 | 1600 | |

Height | mm | 2750 | 2710 | |

Specification | Unit | PR9 150/3100 | PR9 150/4100 | |

Max. Bending Force | KN | 1500 | 1500 | |

Max. Bending Length | mm | 3100 | 4100 | |

Column Distance | mm | 2700 | 3700 | |

Throat Depth | mm | 420 | 420 | |

Ram Stroke | mm | 265 | 265 | |

Closed Height | mm | 530 | 530 | |

Approaching Speed | mm/s | 180 | 180 | |

Working Speed | mm/s | 11 | 11 | |

Return Speed | mm/s | 150 | 150 | |

Main Motor Power | Kw | 15 | 15 | |

CNC System | Holland Delem DA66T or DA52S or DA53T or T-3500T CNC system controlling X, Y1, Y2, R, Z1, Z2 axes and mechanical crowning. | |||

Oil Tank Capacity | L | 440 | 600 | |

No. of Oil Tank | no. | 3 | 4 | |

X | Accuracy | mm | ±0.10 | ±0.1 |

Stroke | mm | 500 | 500 | |

Speed | mm | 500 | 400 | |

Power | kw | 0.85 | 0.85 | |

R | Accuracy | mm | ±0.10 | ±0.1 |

Stroke | mm | 200 | 200 | |

Speed | mm | 200 | 200 | |

Power | kw | 0.85 | 0.85 | |

Z1,Z2 | Accuracy | mm | ±0.10 | ±0.1 |

Speed | mm | 1200 | 1200 | |

Stroke | mm | 1850 | 2800 | |

Power | kw | 0.75 | 0.75 | |

Outline Dimension | Length | mm | 3470 | 4470 |

Width | mm | 1720 | 1720 | |

Height | mm | 2700 | 2710 | |

No. | Name | Model | Brand | |

1 | CNC System | DA66T/T-3500T/DA52S or DA53T CNC System | Holland DELEM | |

2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA OR YASAKAWA | |

3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA OR YASAKAWA | |

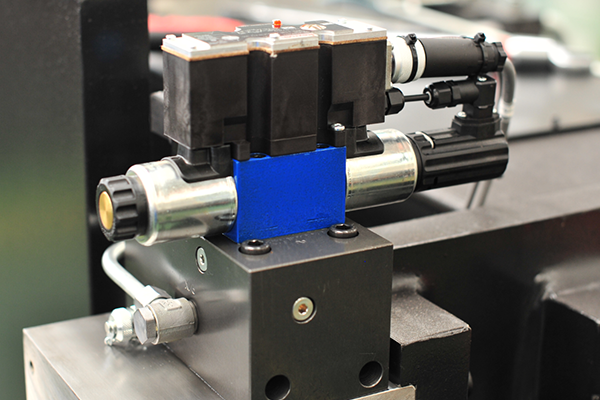

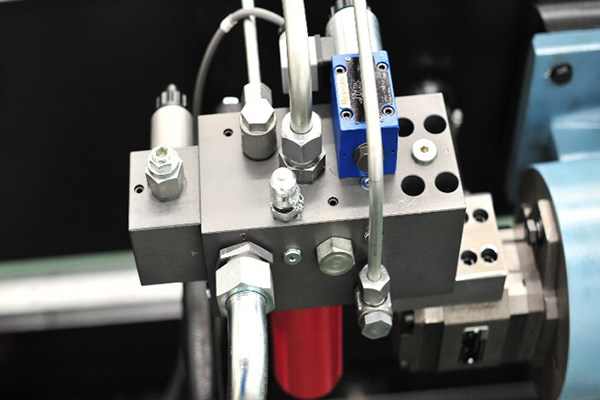

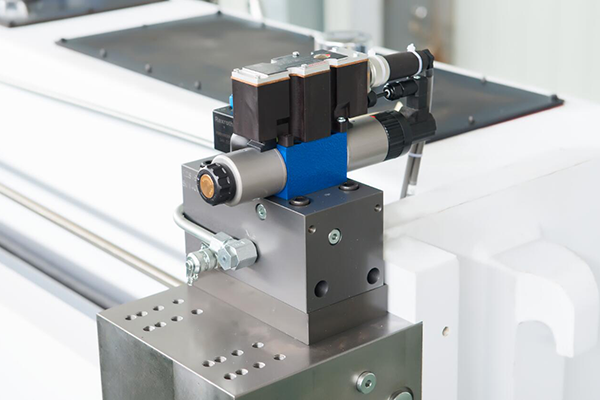

4 | Hydraulic System | Electro-hydraulic system | Germany Bosch-Rexroth or Germany HOERBIGER | |

Synchronization controlling assembly | a. pressure valve | |||

b. active valve | ||||

c. proportional servo valve etc. | ||||

Hydraulic controlling assembly | a. cartridge valve | |||

b. proportional pressure valve | ||||

c. selector valve | ||||

d. proportional decompress valve | ||||

e. pressure valve etc. | ||||

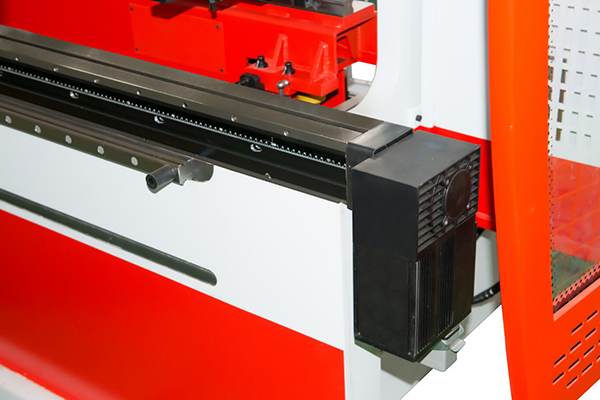

5 | Linear guideway | 35A---760L OR 35E-760L | THK OR PMI | |

6 | Ballscrew | 25/20-1000L or R25/20-880/1000 | THK OR PMI | |

7 | Oil pump | PGH3-2X/016RE071VU2 | Germany Rexroth | |

8 | Complete set of sealing ring in oil cylinder | USA PARKER | USA PARKER | |

9 | Complete set of high pressure pipeline | 1.GE16 ZSR 3/4EDCF | USA PARKER、EO-2 pipe joint or Germany VOSS pipe joint | |

2.GE28 LR3/4EDOMDCF | ||||

3.W10 ZLCF | ||||

4.TH10 ZLR KDSCF | ||||

5.WH10 ZSR KDSCF etc. | ||||

10 | Coupling | R38 25/42 | Germany KTR | |

11 | AC contactor | LC1-D1810B7、LC1-D0910B7N etc. | Schneider | |

12 | Proximity switch | TP-SM5P2 etc. | TEND | |

13 | Terminal lead | UK2.5B、UK10N etc. | Phoenix | |

14 | Button | XB2-BVB3LC etc. | Schneider | |

15 | Painting | Holland SIKKENS | ||

16 | Crowning | National brand( standard) | SREE/UNION | |

17 | Crowning | Imported(option) | VILLA | |

18 | Front supporter | standard | JFY | |

PR9 100

No. | Name | Model | Brand | |

1 | CNC System | DA66T or DA52S or DA53T or T-3500T CNC System | Holland DELEM | |

2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA OR YASAKAWA | |

3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA OR YASAKAWA | |

4 | Hydraulic System | Electro-hydraulic system | Germany Bosch-Rexroth or Germany HOERBIGER | |

Synchronization controlling assembly | a. pressure valve | |||

b. active valve | ||||

c. proportional servo valve etc. | ||||

Hydraulic controlling assembly | a. cartridge valve | |||

b. proportional pressure valve | ||||

c. selector valve | ||||

d. proportional decompress valve | ||||

e. pressure valve etc. | ||||

5 | Linear guideway | 35A-760L OR 35E-760L | THK OR PMI | |

6 | Ballscrew | 20/25-880/1000 OR R25/20-880/1000 | THK OR PMI | |

7 | Oil pump | PGH4-3X/032RE071VU2 | Germany Rexroth | |

IPVAP5-32 | Germany VOITH | |||

HQI3-32 | Germany Eckerle | |||

8 | Complete set of sealing ring in oil cylinder | USA PARKER | USA PARKER | |

9 | Complete set of high pressure pipeline | 1.GE16 ZSR 3/4EDCF | USA PARKER、EO-2 pipe joint or Germany VOSS pipe joint | |

2.GE28 LR3/4EDOMDCF | ||||

3.W10 ZLCF | ||||

4.TH10 ZLR KDSCF | ||||

5.WH10 ZSR KDSCF etc. | ||||

10 | Coupling | R38 25/42 | Germany KTR | |

11 | AC contactor | LC1-D1810B7、LC1-D0910B7N etc. | Schneider | |

12 | Proximity switch | TP-SM5P2 etc. | TEND | |

13 | Terminal lead | UK2.5B、UK10N etc. | Phoenix | |

14 | Button | XB2-BVB3LC etc. | Schneider | |

15 | Painting | KAILEDI | ||

16 | Crowning | National brand( standard) | SREE/UNION | |

17 | Crowning | Imported(option) | VILLA | |

18 | Front supporter | standard | JFY | |

No. | Name | Model | Brand | ||

1 | CNC System | DA66T or DA52S or DA53T or T-3500T CNC System | Holland DELEM | ||

2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA OR YASAKAWA | ||

3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA OR YASAKAWA | ||

4 | Hydraulic System | Electro-hydraulic system | Germany Bosch-Rexroth | ||

Synchronization controlling assembly | a. pressure valve | ||||

b. active valve | |||||

c. proportional servo valve etc. | |||||

Hydraulic controlling assembly | a. cartridge valve | ||||

b. proportional pressure valve | |||||

c. selector valve | |||||

d. proportional decompress valve | |||||

e. pressure valve etc. | |||||

5 | Linear guideway | 35A-760L OR 35E-760L | THK OR PMI | ||

6 | Ballscrew | 20/25-880/1000 OR R25/20-880/1000 | THK OR PMI | ||

7 | Oil pump | PGH4-3X/032RE071VU2 | Germany Rexroth | ||

IPVAP5-32 | Germany VOITH | ||||

HQI3-32 | Germany Eckerle | ||||

8 | Complete set of sealing ring in oil cylinder | USA PARKER | USA PARKER | ||

9 | Complete set of high pressure pipeline | 1.GE16 ZSR 3/4EDCF | USA PARKER、EO-2 pipe joint or Germany VOSS pipe joint | ||

2.GE28 LR3/4EDOMDCF | |||||

3.W10 ZLCF | |||||

4.TH10 ZLR KDSCF | |||||

5.WH10 ZSR KDSCF etc. | |||||

10 | Coupling | R38 25/42 | Germany KTR | ||

11 | AC contactor | LC1-D1810B7、LC1-D0910B7N etc. | Schneider | ||

12 | Proximity switch | TP-SM5P2 etc. | TEND | ||

13 | Terminal lead | UK2.5B、UK10N etc. | Phoenix | ||

14 | Button | XB2-BVB3LC etc. | Schneider | ||

15 | Painting | KAILEDI | |||

16 | Crowning | National brand( standard) | SREE/UNION | ||

17 | Crowning | Imported(option) | VILLA | ||

18 | Front supporter | standard | JFY | ||

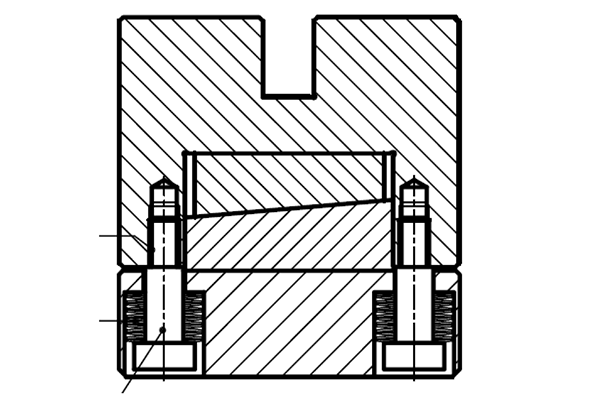

(1) The machine is compensated by a two-way adjusting structure, which can satisfy the compensation of the transverse and longitudinal direction of the machine.

(2) The dense point compensation method is adopted to make the bending accuracy more accurate.

(3) the bending of the same plate thickness material compensation once in place, different from the hydraulic compensation and back and forth movement of the structure, mechanical compensation greatly reduce the machine tool workbench fatigue deformation, improve its service life;

(4) Use special reducer and high precision potentiometer to control accurately control the accuracy of compensation.

(5) Different from the three-plate structure of hydraulic compensating worktable, this device adopts single-plate worktable design, which can effectively prevent interference in bending workpiece.

1.Full WINDOWS® operation system, can realize instant machine shutdown;

2.Selection of multi languages with convenient operation;

3.Fashionable appearance design with people-oriented operation;

4.Intelligent module structure, the system can be extended into 24 axes;

5.17 "TFT true color LCD display, 2D graphical programming;

6.Built-in PLC to reduce circuit design and increase reliability;

7.USB mouse port, keyboard port;

8.Auto accumulation of machine working time and bending times;

9.Bending procedure auto compilation and bending simulation;

10.Zoom free of machine appearance, tool and workpiece at the rate of 1:1:1 with graphic format;

11.Digital, graphic and other means of die programming, flat die, large arc die, multi V groove mold, variable V groove mold;

12.Automatic angle correction database, self learning bending tolerance table and omni-directional collision detection function, eliminate waste products;

13.Error alarm system to avoid mal-operation;

14.Memory capacity 1G

15.Remote diagnosis;

16.Machine special analysis software, real-time monitoring;

17.Special off-line programming software can reduce programming time and increase efficiency;

18.Embedded file management system, text editor;

19.Tandem operation;

20.The operation panel is equipped with emergency stop, manual moving slider and ergonomics perspective.

1 Use real-time WINDOWS operating system, can realize the instantaneous shutdown;

2 kinds of language options, can be set to the English interface, easy to operate;

3 fashion design, easy to operate, reflect the people-oriented;

4 standard four axis, additional modules, supports up to six axis;

5.10 "TFT true color screen, LCD touch screen, multi touch, two-dimensional graphics programming, 3D display;

6 Built-in PLC function, reduce the circuit design, increase the reliability;;

7.USB mouse interface, keyboard interface;;

8.Automatic working hours and bending times;

9.Digital and 2D graphics full touch programming, bending process 3D view, bending process automatic compiling and bending simulation;

10.Machine shape, mold and workpiece are freely zoomed in 1:1:1 according to graphics.

11,Digital, graphic and other means of die programming, flat die, large circular arc die, multi V groove mold, variable V groove mold;

12.Error alarm system to avoid mal-operation;

13.Memory capacity 1G

14.Machine special analysis software, real-time monitoring;

15.Embedded file management system, text editor;

16.Tandem operation;

17.The operation panel is equipped with emergency stop, manual moving slider and ergonomics perspective.

1.Use real-time WINDOWS operating system, can realize the instantaneous shutdown

2.Selection of multi languages with convenient operation;

3.Fashionable appearance design with people-oriented operation;

4.Intelligent modular structure, the system can extend the 4 axis flexibly

5.7"TFT LCD display;

6.Built-in PLC to reduce circuit design and increase reliability;

7.USB mouse port, keyboard port, RS232 port, safety PLC port;

8.Auto accumulation of machine working time and bending times;

9.Digital programming;

10.Digital mode mold programming;

11.The automatic angle correction database;

12.Error warning system to prevent misoperation;

13.The memory capacity is 64M;

14.Special analysis software, real-time monitoring;

15.Tandem operation;

16.The operation panel is equipped with urgent stop.

1.Use DELEM-LINUX operating system, can realize the instantaneous shutdown

2.Selection of multi languages with convenient operation;

3.Fashionable appearance design with people-oriented operation;

4.Intelligent modular structure, the system can extend the 4 axis flexibly

5.10"TFT LCD display;

6.Built-in PLC to reduce circuit design and increase reliability;

7.USB mouse port, keyboard port, RS232 port, safety PLC port;

8.Auto accumulation of machine working time and bending times;

9.Digital touching programming;

10.Digital mode mold programming;

11.The automatic angle correction database;

12.Error warning system to prevent misoperation;

13.The memory capacity is 64M;

14.Special analysis software, real-time monitoring;

15.Embedded file management system, text editor

16.Tandem operation;

17.The operation panel is equipped with urgent stop.

No. | Description | Quantity | Remark |

1 | Operations Files | One set | |

2 | Inner Hex Socket Spanner | One set | |

3 | Grease Gun | One no. | |

4 | Grounding Bolt | One set | |

5 | Adjusting Bolt | One set | |

6 | Foot Control | One no. | |

7 | Standard Tooling | One set |

1. Hydraulic oil: imported VG46# anti-wear hydraulic oil; and the required oil mass depend on the machine specification;

2. Power: 380V,50HZ, voltage fluctuation 10%--5%

3. Environment temperature: 0°C - +40°C

4. Environment humidity: relative humidity 20-80%RH(non-condensing)

5. Keep away from the strong vibration source and electromagnetic interference

6. Little dust, no harmful or corrosive gas

7. Prepare the foundation according to the foundation drawing

8. Select the relative personnel with certain education background for a long-term arrangement as machine operator.

No. | Description | Quantity | Remark |

1 | Operations Files | One set | |

2 | Inner Hex Socket Spanner | One set | |

3 | Grease Gun | One no. | |

4 | Grounding Bolt | One set | |

5 | Adjusting Bolt | One set | |

6 | Foot Control | One no. | |

7 | Standard Tooling | One set |

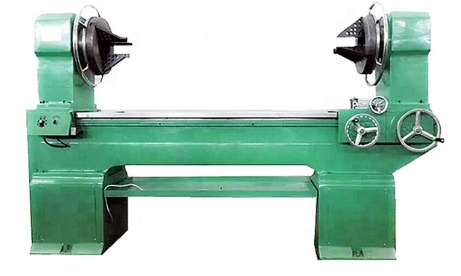

Model | Nominal Pressure(KN) | Table Length(mm) | Column Distance (mm) | Throat Deep(mm) | Ram Stroke(mm) | Max Day height(mm) | Oil Tank (L) |

HPC-40/2000 | 400 | 2000 | 1650 | 200 | 150 | 400 | 260 |

HPC-63/2500 | 630 | 2500 | 2050 | 250 | 200 | 460 | 300 |

HPC-80/2500 | 800 | 2500 | 2050 | 250 | 200 | 460 | 300 |

HPC-100/3200 | 1000 | 3200 | 2700 | 400 | 200 | 460 | 380 |

HPC-100/4000 | 1000 | 4000 | 3200 | 430 | 200 | 460 | 380 |

HPC-125/3200 | 1250 | 3200 | 2700 | 430 | 200 | 470 | 380 |

HPC-125/4000 | 1250 | 4000 | 3200 | 430 | 200 | 470 | 380 |

HPC-160/3200 | 1600 | 3200 | 2700 | 430 | 200 | 500 | 400 |

HPC-160/4000 | 1600 | 4000 | 3100 | 430 | 200 | 500 | 400 |

HPC-200/3200 | 2000 | 3200 | 2700 | 430 | 200 | 500 | 560 |

HPC-200/4000 | 2000 | 4000 | 3100 | 430 | 200 | 500 | 670 |

HPC-250/3200 | 2500 | 3200 | 2650 | 400 | 250 | 520 | 560 |

HPC-250/4000 | 2500 | 4000 | 3100 | 400 | 250 | 520 | 670 |

HPC-250/5000 | 2500 | 5000 | 4000 | 400 | 250 | 520 | 800 |

HPC-250/6000 | 2500 | 6000 | 4800 | 400 | 250 | 520 | 1000 |

HPC-320/3200 | 3200 | 3200 | 2650 | 400 | 250 | 480 | 600 |

HPC-320/4000 | 3200 | 4000 | 3100 | 400 | 250 | 480 | 720 |

HPC-320/5000 | 3200 | 5000 | 4000 | 400 | 250 | 480 | 968 |

HPC-320/6000 | 3200 | 6000 | 4800 | 400 | 250 | 480 | 1187 |

HPC-400/3200 | 4000 | 3200 | 2650 | 500 | 320 | 660 | 600 |

HPC-400/4000 | 4000 | 4000 | 3100 | 500 | 320 | 660 | 720 |

HPC-400/5000 | 4000 | 5000 | 4000 | 500 | 320 | 660 | 968 |

HPC-400/6000 | 4000 | 6000 | 4800 | 500 | 320 | 660 | 1187 |

HPC-500/4000 | 5000 | 4000 | 3100 | 600 | 320 | 760 | 870 |

HPC-500/5000 | 5000 | 5000 | 4000 | 600 | 320 | 760 | 1146 |

HPC-500/6000 | 5000 | 6000 | 4800 | 600 | 320 | 760 | 1400 |

HPC-600/6000 | 6000 | 6000 | 4800 | 600 | 320 | 800 | 1400 |

HPC-800/6000 | 8000 | 6000 | 4800 | 650 | 350 | 700 | 2100 |

HPC-1000/6000 | 10000 | 6000 | 4800 | 600 | 400 | 980 | 2100 |

HPC-1200/6000 | 12000 | 6000 | 4800 | 1600 | 450 | 1550 | 2100 |

HPC-1600/6000 | 16000 | 6000 | 4800 | 1100 | 450 | 1200 | 3900 |

HPC-1600/9000 | 16000 | 9000 | 6500 | 1100 | 450 | 1200 | 3900 |

HPC-2200/8000 | 22000 | 8000 | 6000 | 1100 | 450 | 1200 | 3460 |