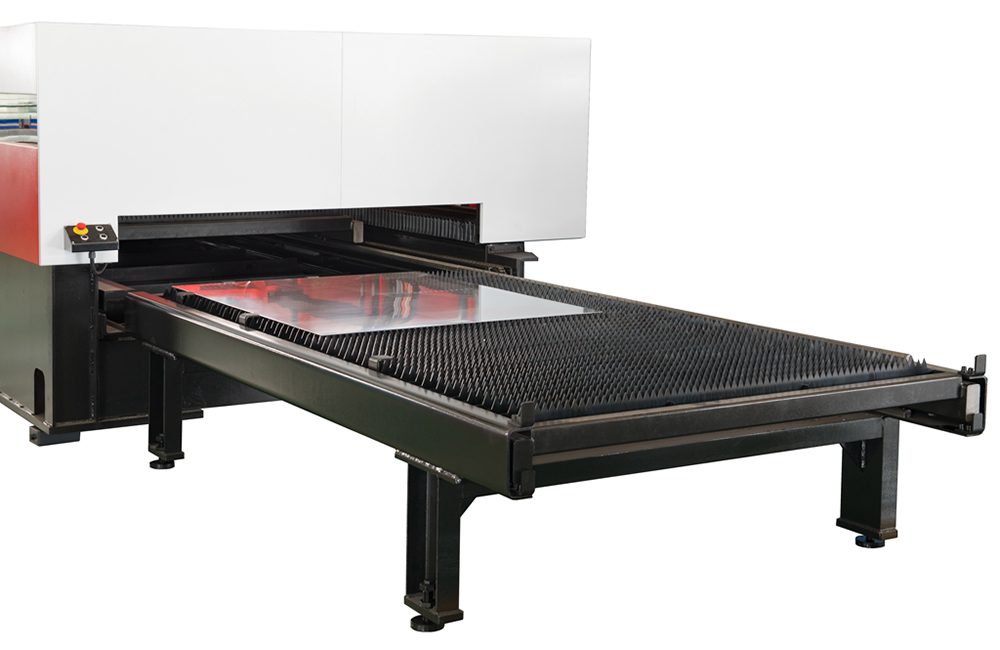

EFC3015 CNC laser cutting machine characters:EFC3015 CNC laser cutting machine is a new type of laser cutting machine. The structure has high rigidity, good stability, high cutting efficiency and high machining precision. The products are of high flexibility, safety, easy operation and low energy consumption. It belongs to environmental protection product, the processed plate size: 3000 * 1500mm; with the safety shield and the shuttle table. The overall layout is compact and reasonable.

Low consumption - laser does not need gas;

Low energy consumption, energy saving, environmental protection, low power consumption;

Modular structure, cooling system and light source system and laser source are integrated together;

The high stability - power - time feedback control system with laser power, power stability 1%;

Maintenance costs are low - fiber head using the mirror protection technology, if polluted, only need to change the protection lens;

EFC 3015 technology:

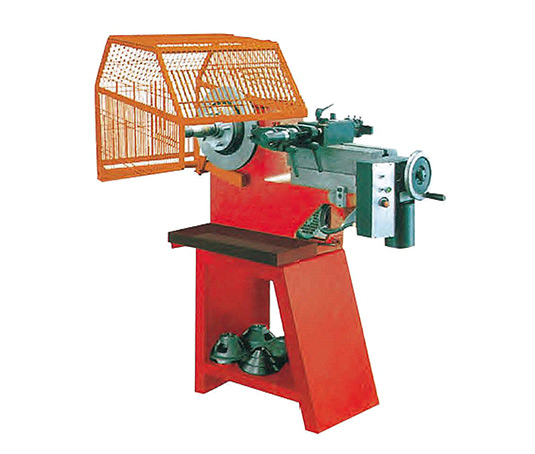

A. adopts imported precise linear guide, import precise gear rack drive, ensure the positioning accuracy and repeatability.

B. Gantry type dual motor direct drive structure makes the whole structure of the product is compact, and the rigidity is good, and the height of the whole machine is lower.

Product structure:

The main body is welded of steel plates, after the rough machining, dealing with vibration aging stress. Through precise machining, provides a solid platform and level for the motion system.

The beam adopts flexible structure, with adaptive thermal expansion and contraction function, accounting through the finite element method. Beam parts is mounted to the bed by precise linear rolling guide. Guide, gear and rack are equipped with flexible protective cover, so as to avoid being contaminated by dust.

The product is equipped with shuttle worktable, easy to load and unload material when cutting. Below the worktable equipped with dust partition parts and material collecting groove, matching with wheel discharging car, scraps can directly enter into the waste discharging car.